1. DEFINITION OF NONWOVEN

An average person is unlikely to be familiar with the term Nonwovens and a few decades back there were no experts in this field. When the consumer hears the term

Nonwovens it makes him think of something, which is not like traditional woven fabrics, something modern, advanced, hygienic, but he is not aware of any specific types

of materials among those which carry the same name. But now the precise meaning of the term is somewhat clearer to the experts. According to the experts, Nonwovens is

a class of textiles/sheet products, unique in industry, which is defined in the negative; that is, they are defined in what they are not. Nonwovens fabrics are

different than the conventional textile fabrics and paper. Nonwovens are not based on yarns and (with frequent exceptions) do not contain yarns. They are based on webs

of individual fibers. Nonwovens are different than paper in that nonwovens usually consist entirely or at least contain a sizeable proportion of long fibers and/or

they are bonded intermittently along the length of the fibers. Although paper consists of fiber webs, the fibers are bonded to each other so completely that the entire

sheet comprises one unit. In nonwovens we have webs of fibers where fibers are not as rigidly bonded and to a large degree act as individuals [1].

The definitions of the nonwovens most commonly used nowadays are those by the Association of the Nonwovens Fabrics Industry (INDA) and the European Disposables and

Nonwovens Association (EDANA).

1.1.INDA DEFINITION:

Nonwovens are a sheet, web, or bat of natural and/or man-made fibers or filaments, excluding paper, that have not been converted into yarns, and that are bonded to

each other by any of several means.

The various methods for bonding are:

a) Adding an adhesive

b) Thermally fusing the fibers or filaments to each other or to the other meltable fibers or powders.

c) Fusing fibers by first dissolving, and then resolidifying their surfaces.

d) Creating physical tangles or tuft among the fibers.

e) Stitching the fibers or filaments in place.

1.2.EDANA DEFINITION:

Nonwovens are a manufactured sheet, web or bat of directionally or randomly oriented fibers, bonded by friction, and/or cohesion and/or adhesion, excluding paper or

products which are woven, knitted, tufted stitch bonded incorporating binding yarns or filaments, or felted by wet milling, whether or not additionally needled. The

fibers may be of natural or man-made origin. They may be staple or continuous or be formed in situ.

2.APPLICATIONS OF NONWOVENS

Nonwovens find numerous applications ranging from baby diapers to industrial high performance textiles. Some of the important areas where nonwovens are treated as

primary alternative for traditional textiles as Geotextiles, materials for building, thermal and sound insulating materials, hygienic and health care textiles and

automotive industries. Nonwovens are also used in cover stocks, agriculture, aerospace, home furnishings etc. Although it is not possible to list all the applications

of nonwovens, some of the important applications are listed in Table 1 [2].

|

Table 1 - Products That Use Nonwovens

|

Agriculture and Landscaping

|

Home Furnishings

|

Industrial/Military

|

Crop Covers

|

Furniture construction sheeting

|

Coated fabrics

|

Turf protection products

|

Insulators, arms and back

|

Filters

|

Nursery overwintering

|

Cushion ticking

|

Semiconductor polishing pads

|

Weed control fabrics

|

Dust covers

|

Wipers

|

Root bags

|

Decking

|

Clean room apparel

|

Containers

|

Skirt linings

|

Air conditioning filters

|

Capillary matting

|

Pull strips

|

Military clothing

|

|

Bedding construction sheeting

|

Abrasives

|

Automotive

|

Quilt backing

|

Cable insulation

|

Trunk applications

|

Dust covers

|

Reinforced plastics

|

Floor covers

|

Flanging

|

Tapes

|

Side liners

|

Spring wrap

|

Protective clothing, lab coats

|

Front and back liners

|

Insulators

|

Sorbents

|

Wheelhouse covers

|

Quilt backings

|

Lubricating pads

|

Rear shelf trim panel covers

|

Blankets

|

Flame barriers

|

Seat applications

|

Wallcovering backings

|

Packaging

|

Listings

|

Acoustical wallcoverings

|

Conveyor belts

|

Cover slip sheets

|

Upholstery backings

|

Display felts

|

Foam reinforcements

|

Pillows, pillow cases

|

Papermaker felts

|

Transmission oil filters

|

Window treatments

|

Noise absorbent felt

|

Door trim panel carpets

|

Drapery components

|

|

Door trim panel padding

|

Carpet backings, carpets, and

|

Leisure, Travel

|

Vinyl, landau cover backings

|

Pads

|

Sleeping bags

|

Molded headliner substrates

|

Mattress pad components

|

Tarpaulins, tents

|

Hood silencer pads

|

|

Artificial leather, luggage

|

Dash insulators

|

Health Care

|

Airline headrests, pillow cases

|

Carpet tufting fabric and under

|

Surgical: caps, gowns, masks,

|

|

Padding

|

Shoe covers

|

Personal Care and Hygiene

|

|

Sponges, dressings, wipes

|

Diapers

|

Clothing

|

Orthopedic padding

|

Sanitary napkins, tampons

|

Interlinings

|

Bandages, tapes

|

Training pants

|

Clothing and glove insulation

|

Dental bibs

|

Incontinence products

|

Bra and shoulder padding

|

Drapes, wraps, packs

|

Dry and wet wipes

|

Handbag components

|

Sterile packaging

|

Cosmetic applicators, removers

|

Shoe components

|

Bed linen, underpads

|

Lens tissue

|

|

Contamination control gowns

|

Hand warmers

|

Construction

|

Electrodes

|

Vacuum cleaner bags

|

Roofing and tile underlayment

|

Examination gowns

|

Tea, coffee bags

|

Acoustical ceilings

|

Filters for IV solutions, blood

|

Buff pads

|

Insulation

|

Oxygenators and kidney

|

|

House wrap

|

Dialyzers

|

School, Office

|

Pipe wrap

|

Transdermal drug delivery

|

Bookcovers

|

|

|

Mailing envelopes, labels

|

Geotextiles

|

Household

|

Maps, signs, pennants

|

Asphalt overlay

|

Wipes, wet, dry polishing

|

Floppy disk liners

|

Road and railroad beds

|

Aprons

|

Towels

|

Soil stabilization

|

Scouring pads

|

Promotional items

|

Drainage

|

Fabric softener sheets

|

Pen nibs

|

Dam and stream embankments

|

Dust cloths, mops

|

|

Golf and tennis courts

|

Tea and coffee bags

|

|

Artificial turf

|

Placemats, napkins

|

|

Sedimentation and erosion

|

Ironing board pads

|

|

Control

|

Washcloths

|

|

Pond liners

|

Tablecloths

|

|

Source: The Nonwoven Fabrics Handbook, Association for the Nonwoven Fabrics Industry, Cary, North Carolina

|

3.PRODUCTION AND SHIPMENTS OF NONWOVENS

The Nonwoven industry is one of the fastest growing industries in the world. It is rapidly developing a sophisticated and diverse market. It has been exhibiting an average growth of about 10% over the past twenty years and should continue this rate of growth in the next ten years. The technology in Nonwoven industry has been improved significantly in nearly all available major manufacturing processes, including those of spun bond, meltblown, needle punched, spunlaced, wet laid and dry laid fabrication. The most important point in rapid development and commercial acceptance of nonwovens is the ability to produce materials of special properties in less time and at reasonable prices. The relative production speeds of various textile technologies are compared in Table 2 [3,4].

Table 2 Relative production rates of different Textile technologies

Technology

|

Relative Production Rate

|

Weaving

|

1-6

|

Knitting

|

3-16

|

Nonwovens - web forming:

-Carding

-Spunbond

-Wet-laid

|

120-400

200-2000

2300

|

Nonwovens - bonding

-Stitchbonding

-Needling

-Calendaring

-Hot air bonding

|

40

30-500

2000

5000

|

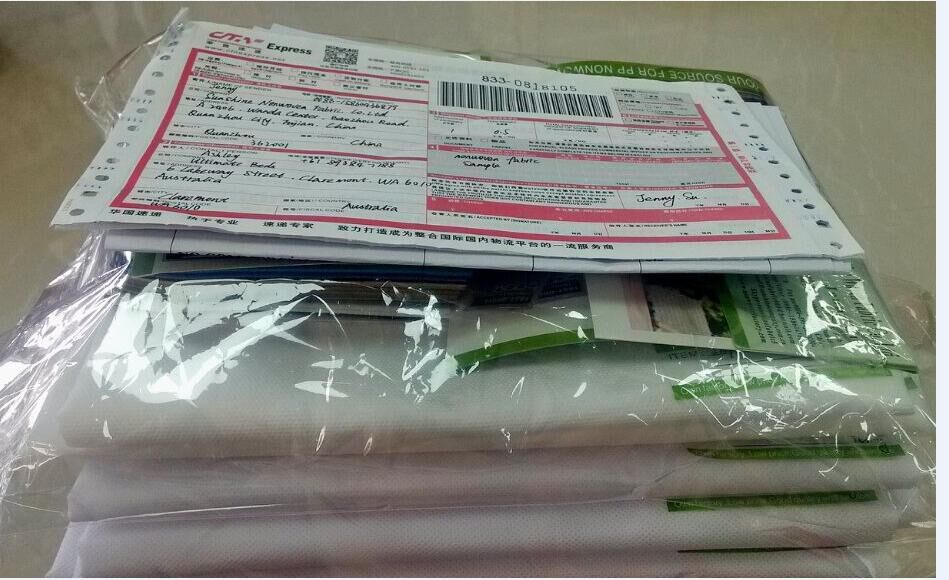

A large number of fibers are available n the market, but the Nonwovens market is mainly dominated by three fibers, namely polyolefin’s, polyester, and rayon. These three fiber types make up a substantial part of the overall Nonwovens markets for fibers [5]. The North American Nonwovens industry is the largest in the world and accounts for almost one third of the worldwide sales of roll goods - around $2.8 billion - in 1997, according to estimates from the Association of the Nonwovens Fabrics Industry (INDA). A major portion of the polyolefin and polyester fiber in the U.S. market is consumed by the Nonwovens industry. Last year (1998), 57% of the polyolefin share was consumed by the Nonwovens industry and only 43% was consumed by all the other industries, in spite of the fact that polyolefin’s are the major raw products for the packaging industry. Even in the case of polyesters, the share has increased to 14%. The major share of polyester fiber goes to high loft industry.

Table 3 U.S. shipments of olefin staple: Nonwovens Vs Other Markets, 1989-1998

YEAR

|

Total U.S.

|

Shipped to Nonwovens

|

All Other

|

1989

|

363

|

195

|

168

|

1990

|

388

|

233

|

155

|

1991

|

438

|

272

|

166

|

1992

|

441

|

259

|

182

|

1993

|

466

|

276

|

190

|

1994

|

489

|

280

|

209

|

1995

|

458

|

267

|

191

|

1996

|

515

|

295

|

220

|

1997

|

542

|

314

|

229

|

1998

|

596

|

339

|

257

|

CAGR, 1989/98

|

5.6%

|

6.4%

|

4.9%

|

Source: Fiber Economics Bureau and Trade Estimates, CAGR- Compound annual growth rate.

Fig 1 US shipment of olefin fibers: Nonwovens Vs other markets 1989-1998